The project

The 270 ton Mooring Spread comprises:

- 9 hydraulic power packs installed in a 20ft container, diesel powered

- 8 hydraulic winches each with a tractive force of 270 tons

- 1 20ft control container

- 9 local control panels

- 8 plates for measuring length and tractive force

- Spare parts

- All hydraulic hoses and data cables

Our approach

Before starting the project, all HPUs and winches were transported to Schoondijke by special transport due to the significant dimensions and weights. In close consultation with our client, an outline scoping document was then drawn up. This was then implemented by the Service department.

Powerpacks:

- Cleaning outside and inside (incl. fuel tanks, hydraulic reservoir and engine room)

- Full technical inspection

- Dismantling pumps for internal inspection

- Replacement of all hoses and expansion joints

- Replace diesel engine vibration isolators

- Modification of panel pressure gauges

- Diverse modifications to E&I

- Full hydraulic maintenance

- Full service of diesel engines

- Recertification (MPI + load test)

- Preservation

- Applying new stickers inside and outside

- Hydraulic schematics set up

- Function test and FAT

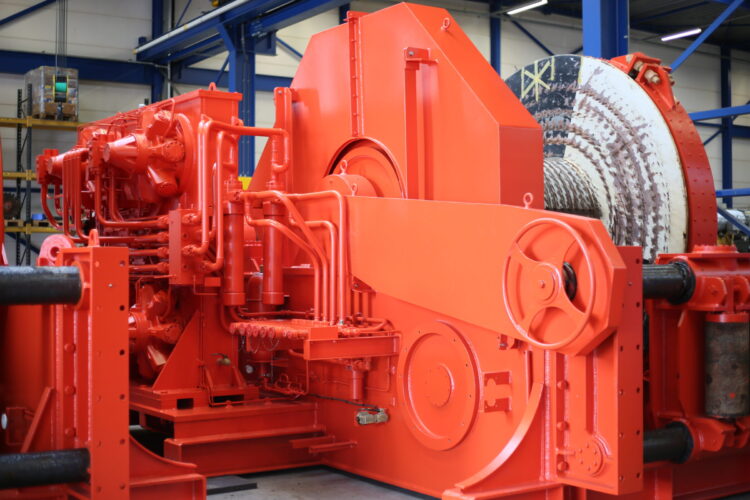

270 ton mooring winches:

- Cleaning outside and inside

- Full technical inspection

- Dismantling motor for internal inspection

- Replacement of all hoses

- Removing water brake

- Repair pipework

- Degreasing and greasing (removing old grease residues, cleaning surfaces and re-greasing)

- Rusty brake surfaces of winch drum

- Inspection of brake bands and linings

- Various repairs and full inspection of E&I

- Recertification (MPI)

- Function test and FAT

- Application of preservative treatments

- Applying new stickers

- Setting up hydraulic schematics