The project

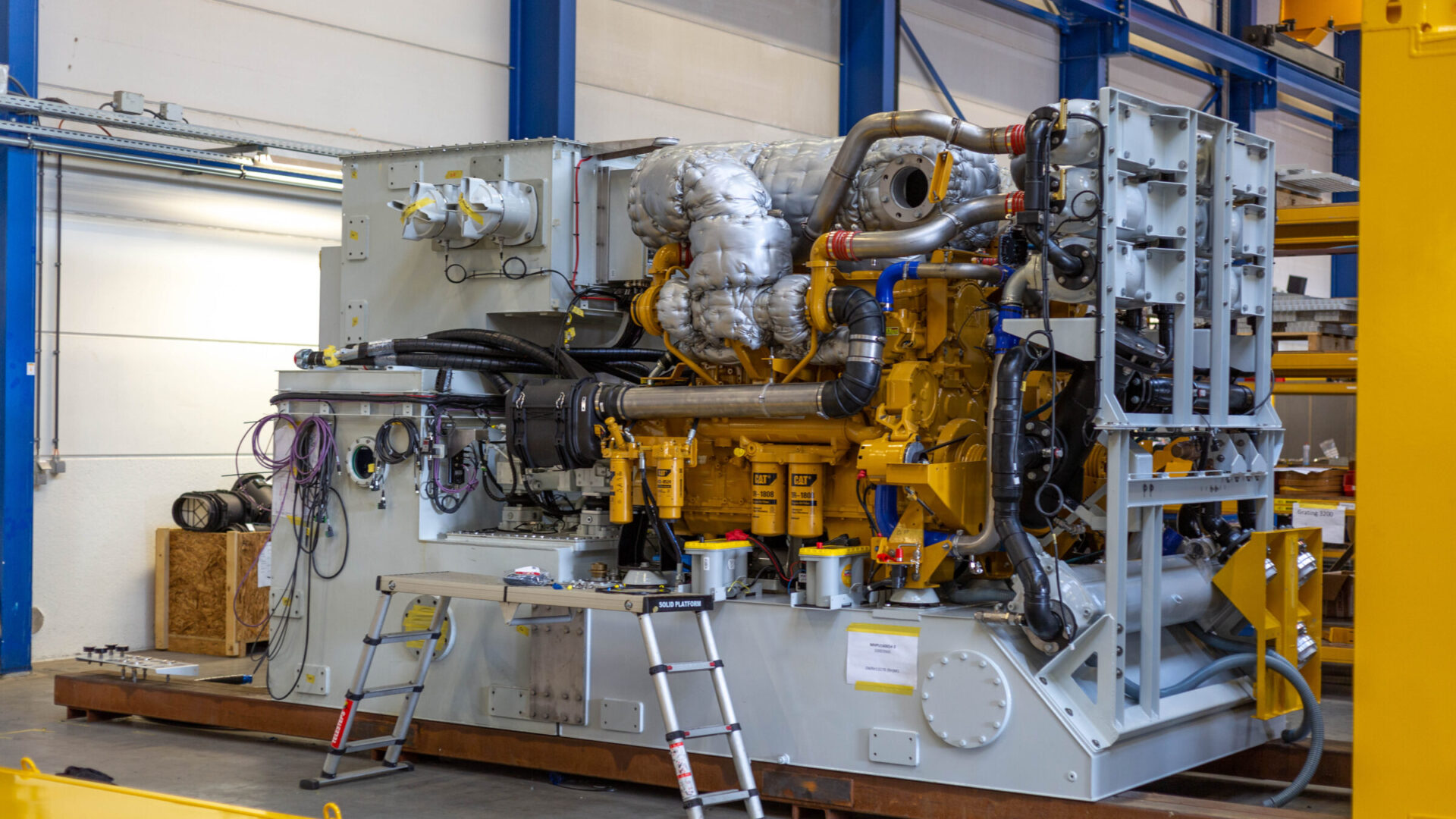

This project involves four powerpacks with a flow of 3200 l/min at 350 bar. These are built with four diesel engines with each two double pumps, all placed in a 40 ft. container. In addition, two powerpacks with a flow of 1600 l/min at 350 bar are mounted in a 20 ft. container. In the 40 ft. containers there are two coupled 1600 l/min powerpacks, each with their own hydraulic and diesel tank, which are connected to each other with a level pipe.

Our solution

To prevent the temperature of the hydraulic oil from becoming too high, the oil is pumped through a cooling system. This system takes advantage of the environment in which these powerpacks are placed: namely seawater. After the oil is cooled by the seawater, it is returned to the hydraulic tank by circulation pumps. These pumps are driven by the auxiliary pump built on the PTO of the engine.

Within a few months, these power packs will drive hydraulic hammers to place the foundations of wind turbines.