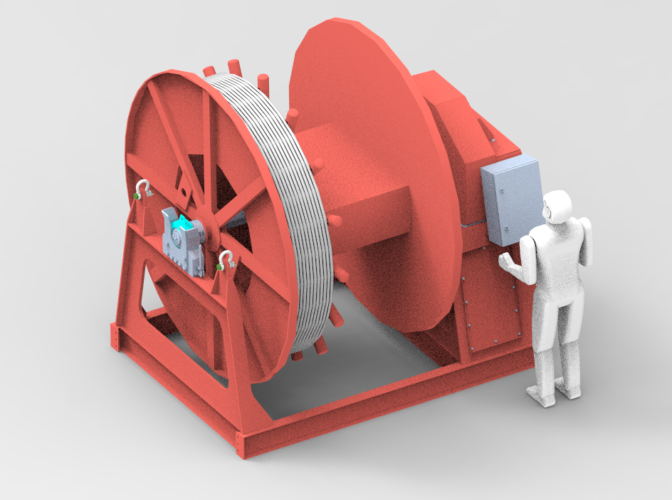

The project

One of the requirements was that the reel must be fully redundant. If one of the hydraulic motors or pumps should fail or present a fault, the machine must be able to continue working (at half speed). Another requirement was that the RDS must have a CT control. The reason being that the umbilical cable must be kept at a constant tension when lowering. The reel drive system is meant for installation on-board of the ‘Balder’ Deepsea Crane Vessel. This vessel is active with regard to activities in the oil fields of Angola.

Our approach

Hydrauvision has designed a reel drive system based on 2 hydraulic motors. They drive the reel through a chain transmission. The reel can be installed and uninstalled quickly by using a specially designed quick-change and coupling system. An HPU was designed for the provision of hydraulic energy with closed system pumps that are dual driven electrically. A proportional pressure control valve was provided for the CT operation. This means that the closed system pumps can be controlled in four quadrants. If the reel is switched at a constant tension (CT), it will always try to keep the cable at the set pulling force. If the pulling force in the cable is too low, the reel will start to heave automatically with such a speed that the pulling force will continue to be constant within a specific margin. If the pulling force becomes too high, the reel will start to lower automatically. The system also has a (wire-connected) remote control.