For high-quality piping, Hydrauvision is the right partner to turn to. The combination of piping, tubing and welding is provided by professional engineers and certified welders. This results in highly qualified professional work. We do this both prefabricated (in our own workshops) and on-site.

Piping

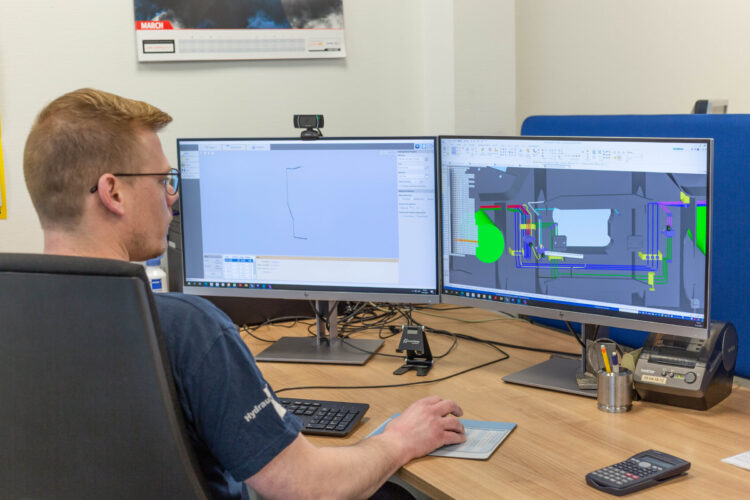

Are you looking for piping with an accuracy up to a millimetre? Hydrauvision Piping specializes in piping with the highest welding and sealing requirements. This work usually begins on the drawing table and ends at your location, with assembly by our professional assemblers. Measuring, advising, engineering, fabricating, constructing and assembling; our engineers realize reliable and leak-free piping that fits within the available space with millimetre precision. In terms of materials, the possibilities are endless, such as stainless steel, steel, aluminum, duplex and CuNiFer. Naturally, we also use our knowledge and expertise to advise you on the right choice of material for your specific maritime, industrial or infrastructural application.

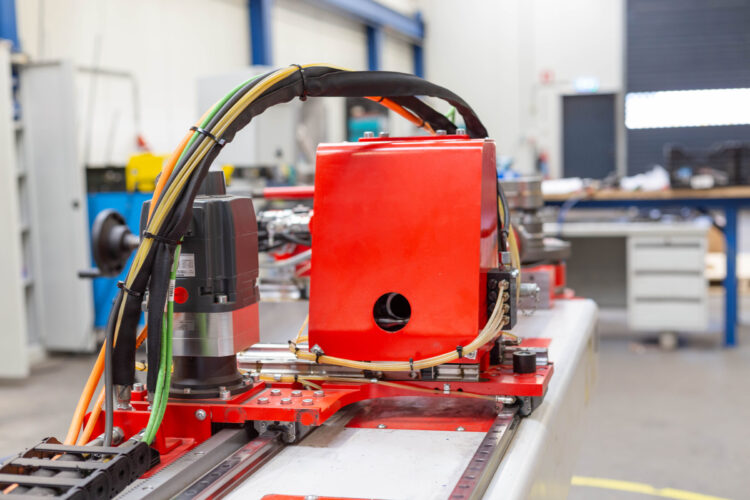

Mobile 3D measuring system

Hydrauvision has a high-tech mobile 3D measuring system to measure bent piping on site or in the workshop. In combination with our CNC bending machine, hydraulic piping can be made perfectly to size. The system is ideal for quickly and accurately replacing existing piping, but also to optimize or adapt them to a new situation, for example if extra components need to be built in. This system consists of a 3D camera and wireless recording system that automatically generates a 3D drawing. Depending on the job, the data can be entered directly into one of the CNC bending machines, even when it comes to complex, multiple-bent piping. In addition, the information can be used by the engineers to optimize the piping before it is forwarded.

Tubing

Besides piping, we have plenty of experience with tubes, in the various sizes and shapes, such as square, rectangular and cylindrical. Our engineers are inventive. They work out your tubing project in such a way that the available space is used optimally. There are plenty of possibilities when it comes to the choice of materials. For example, we work with stainless steel, CuNiFer and steel.

Welding

Hydrauvision only works with certified welders. These are men who have an eye for our clients’ wishes and always strive for the highest quality. In addition to the necessary professional diplomas (Lloyd’s/DNV), they are also certified for various materials, welding positions and wall thicknesses. Our welders also have experience with all possible certifications and requirements, such as the strict ATEX requirements for offshore applications.

Besides the right manpower, we also have high quality equipment, such as various welding units for MIG/MAG (steel and stainless steel) and TIG (steel, stainless steel and aluminum). All this for prefab and on site.

Would you like to know more about the possibilities? Please contact us!